|

Model 2003 Stencil & Pallet Cleaner |

|

|

|

|

Model 2003 Stencil & Pallet Cleaner |

|

|

|

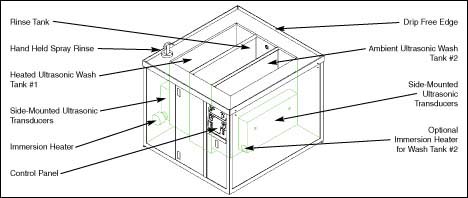

The Model 2003 Stencil & Pallet Cleaner is designed for multiple cleaning applications involving different contaminants and offers an affordable alternative to the user requiring high quality, EPA compliance and guaranteed performance. The standard configuration consists of one ambient ultrasonic wash tank, one heated ultrasonic wash tank and one spray rinse tank allowing the user to safely clean solder paste stencils at ambient temperature while cleaning adhesives and flux residue in the heated wash tank. Separate wash tanks also eliminate the potential of cross contamination between the various cleaning applications.

The Model 2003 is ergonomically designed for easy loading and unloading of large 29-inch (750 mm) stencils without the need of unwieldy baskets or step platforms. The liquid depth of the wash tank is 25-inches to facilitate cleaning only the contaminated portion of large stencils and allowing for a lower overall profile. The remaining 4-inches of the stencil does not contact the wash solution and serves as a convenient "handle" eliminating the need for a stencil basket. The lower profile also eliminates the need of a loading platform that is often required by other ultrasonic stencil cleaners.*

The Smart Sonic Stencil Cleaning Process has been Certified by the California Environmental Protection Agency and Verified by the U.S. EPA's ETV Program. As twice winner of the SMT Vision Award, the Smart Sonic Stencil Cleaning Process has been evaluated and recognized by industry experts. No other cleaning process has reached such high standards.

|

|

|

|

| Specifications: | Model 2003 |

| Overall Dimensions | 45" x 41" x 35"H |

| Wash Tank Dimensions | 9" x 31" x 27"H each |

| Wash Tank Capacity | 32 gallons (121 liters) each |

| Maximum Stencil Size | 29" x 29" (750mm) |

| Ultrasonics | 40 kHz "Sweep Frequency" ** Modular side-mounted for easy maintenance |

| Utilities Required | |

| Electrical | 230 V, 1 Ph, 27 Amps (One heated wash tank) 230 V, 3 Ph, 19 Amps (One heated wash tank) 230 V, 3 Ph, 29 Amps (Two heated wash tanks) Other voltages available. Consult factory. |

| Water | 40 PSI (Soft or DI Water) |

| Applications | Average Cycle Times | 440-R SMT Detergent |

| Wash and Rinse OA Solder Paste | 1/2 - 1 minute | 0-2% |

| Wash and Rinse Wet Solder Paste | 1-2 minutes | 10% |

| Wash and Rinse Dry Solder Paste | 2-4 minutes | 10% |

| Wet SMD Adhesives | 2-4 minutes (100°F Wash) (38° C Wash) | 10% |

| Post Solder Flux Residue Buildup | 2-5 minutes (110°F Wash) (43° C Wash) | 10% |

| Hybrid Inks | Consult Factory |

Specifications are subject to change without notice.

* If the Model 2003 totally immersed a 29-inch stencil, the wash depth would need to be at least 30 inches high and the stencil would need to be placed in a separate basket with handles above the stencil in order to keep the user's hands from contacting the wash solution. The overall height of competitive ultrasonic stencil cleaners range from 43-46 inches compared to only 35-inches of the Model 2003. Because the ergonomic design of the Model 2003 allows the loading and unloading of a 29-inch stencil without the use of a basket, the maximum lifting height for the user is only 64-inches (35" height +29" stencil = 64" lifting height). The lifting height of other ultrasonic stencil cleaners range from 78-81 inches (46" height + 29" stencil + 6" basket handles = 81" lifting height). Plus the weight of the basket! This height would require a loading platform for the user. (If a platform is required, many areas will require a handicap ramp.) The floor space required for loading and unloading could exceed the floor space required for the equipment and the weight of the basket will add to the required lifting load for the user which could require an automated hoist.

** Smart Sonic Stencil Cleaners are powered to meet strict demands of the SMT industry -- powerful enough to remove solder paste, yet delicate enough to safely clean populated misprinted PCBs. High-powered ultrasonics should be avoided.